Steel and Wood Shield [Fabrication]

Metal and Wood Shield

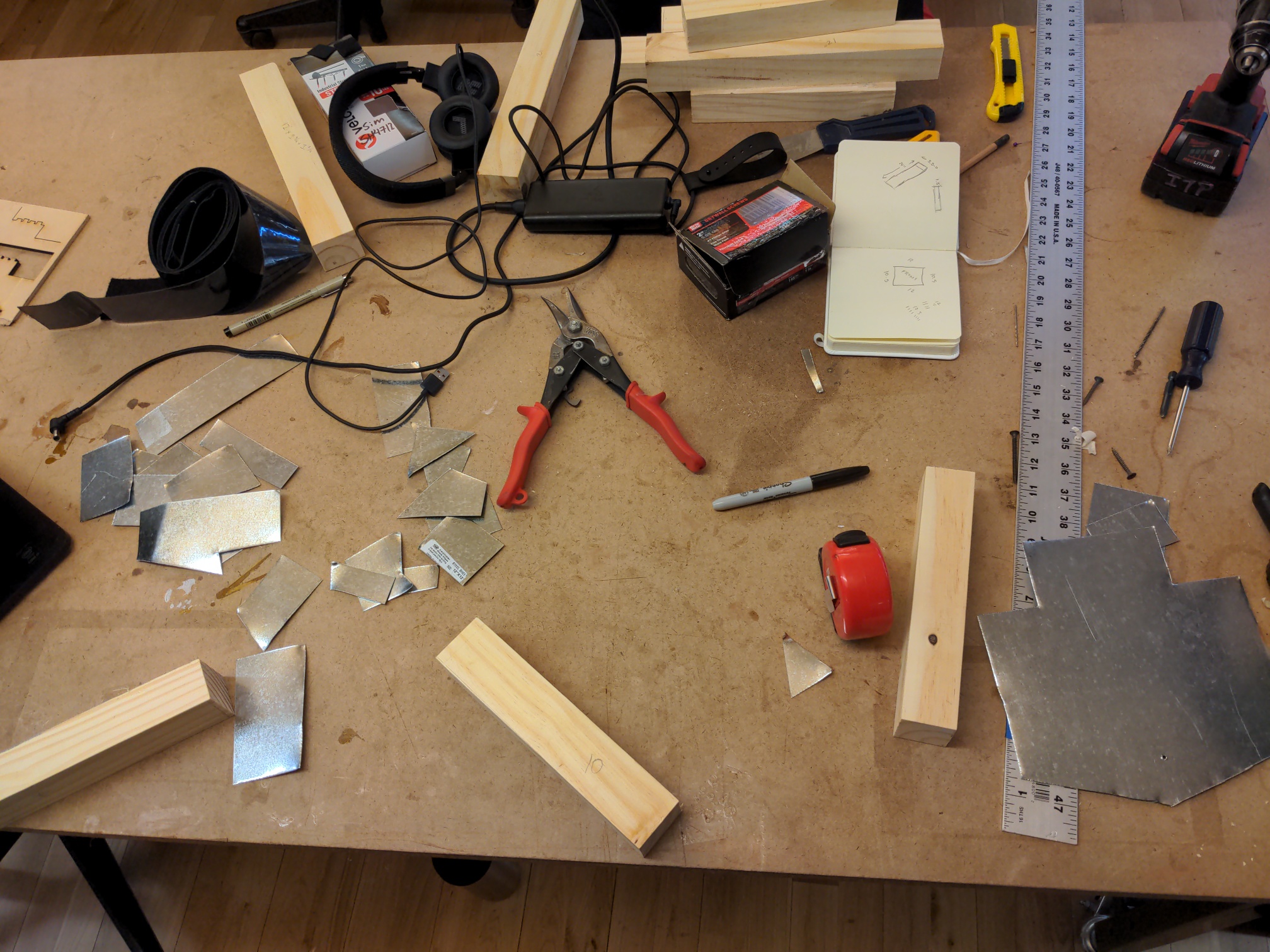

This week I spent a lot of time changing my mind and failing. My main issue was that I simply could not come up with an idea for this week’s assignment that I liked and felt very true to my theme. All I knew was that I want to use sheet metal because it sounds cool and looks cool as well. Anyways I eventually settled on planning to make a display case because it vaguely invoked security and woud be a decent yet hard to mess up challenge with the materials I was using.

I started off my search at the hme dpot where I purchased some 12”x12” sheets of galvanized steel and 5 pre-cut blocks of 2ft by 4” by 2” (in reality 2ft by 3.5” by 1.5”) “premium lumber”. After a short chat with a service worker I also grabbed some fine thread screws, apparently nice for securing metal to wood without messing up the metal.

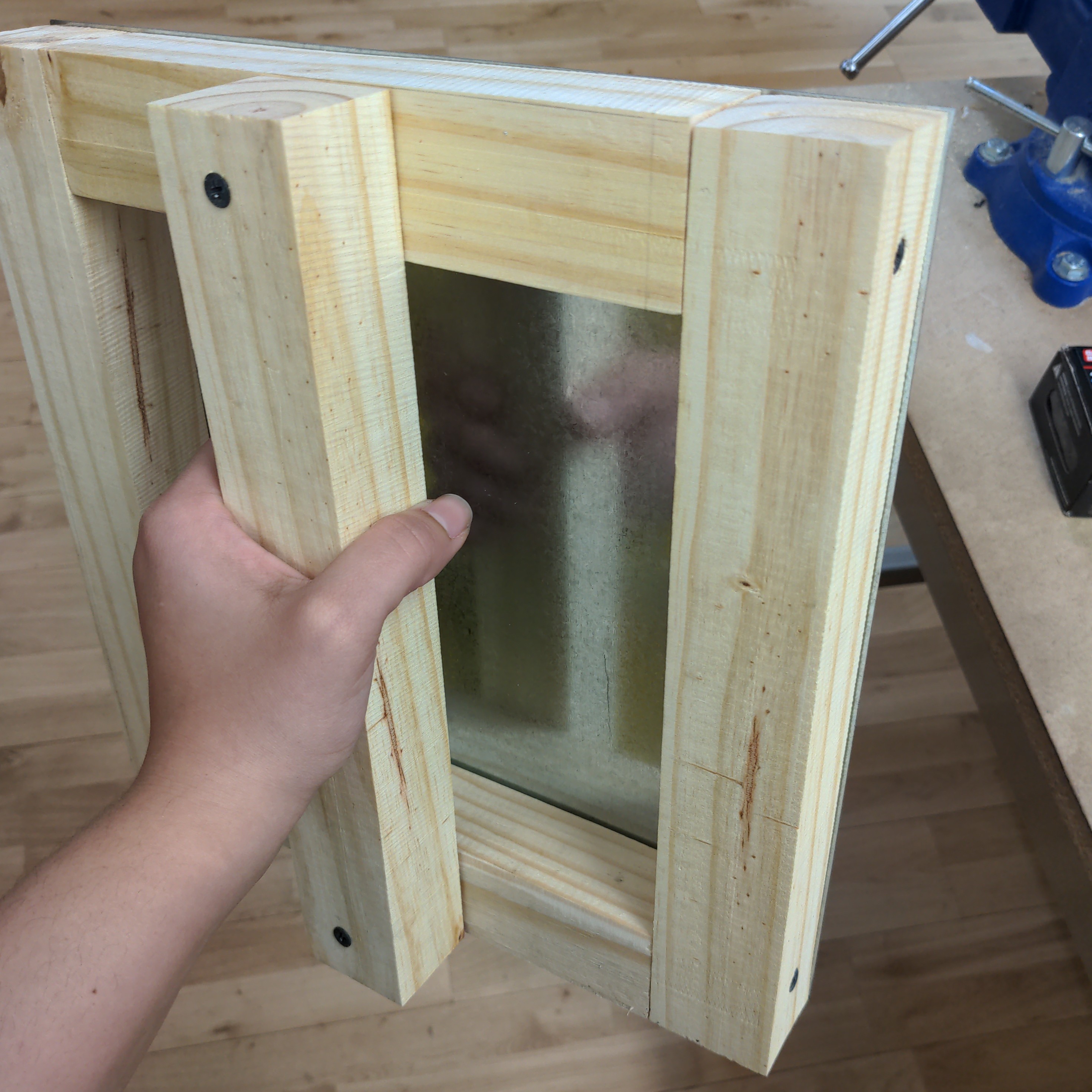

At the shop I got right to work, deciding to build an outline style (edges and corners only / no fill) box frame out of the wood. I decided to use the mitor saw cut four pieces in 12” by 1 3/4” and eight pieces into 10.5” by 1 3/4”, making use of the 1.5” depth measurement to have some pieces fit into the frame nicely to have a perfect cube.

After cutting everything up I did a mock placement test to make sure everything was square. I noticed the box frame was a little big for the metal sheet which I wanted to place over it so I hit the band saw to shave a few centimeters off and returned to find a solid fit.

After sitting and staring at the placement test in the above image for many minutes I came up with the idea to make a shield instead. I asked several shop staff throughout the day about engraving and/or cutting galvanized steel in the laser cutter and everyone seemed to think it was okay so I made a cool shield design and a small test print to give it a shot. Upong printing the test print to the steel I found that nothing happened except for a foul, semi-concerning smell.

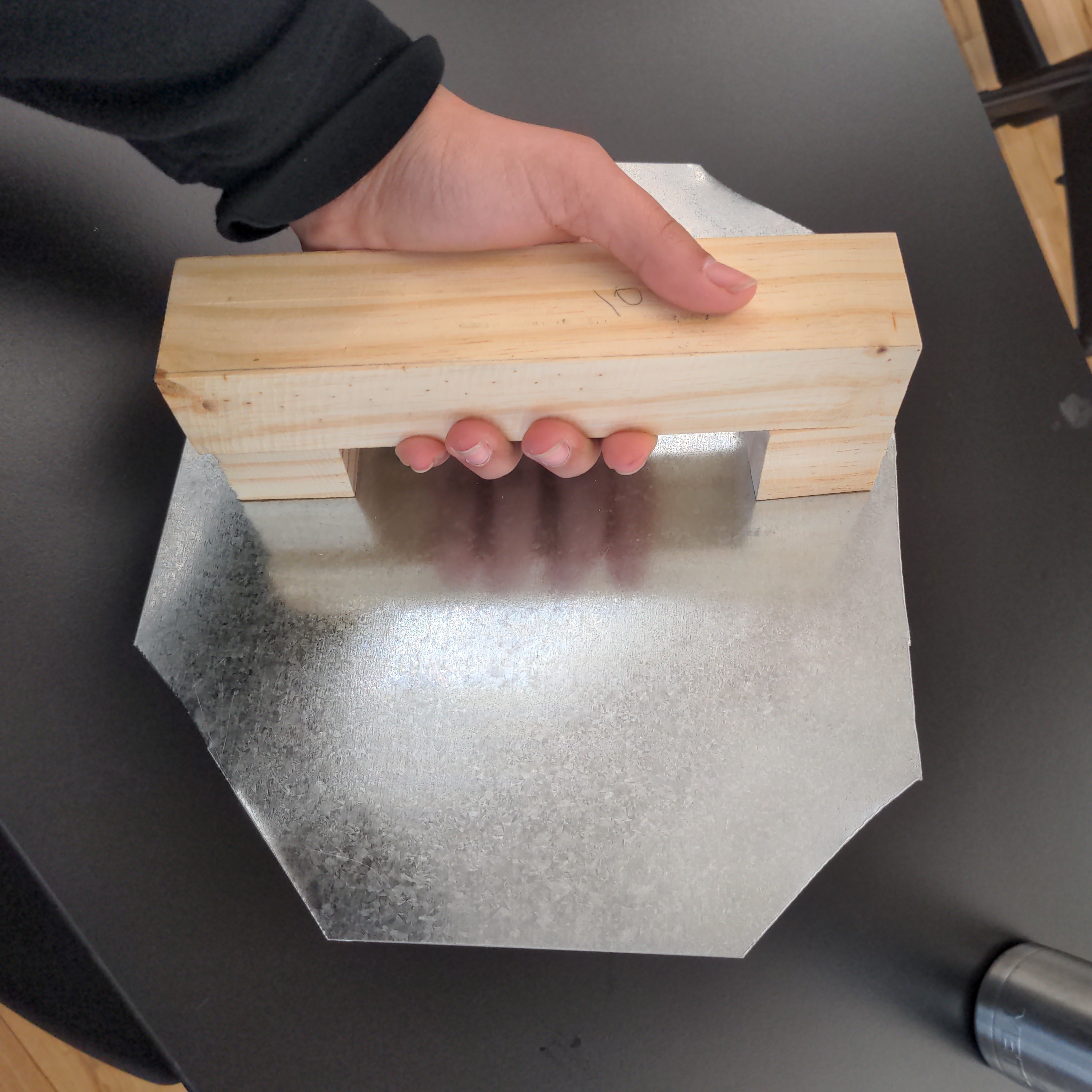

From there I just outlined a design using a ruler and a pencil and got to cutting with the metal sheers. The result was cute but too small for the pieces of wood I already cut to erver as a handle. The bandsaw was broken and the pieces I needed to cut where too small for the mitor saw (learned the hard but not injured or tool breaking way).

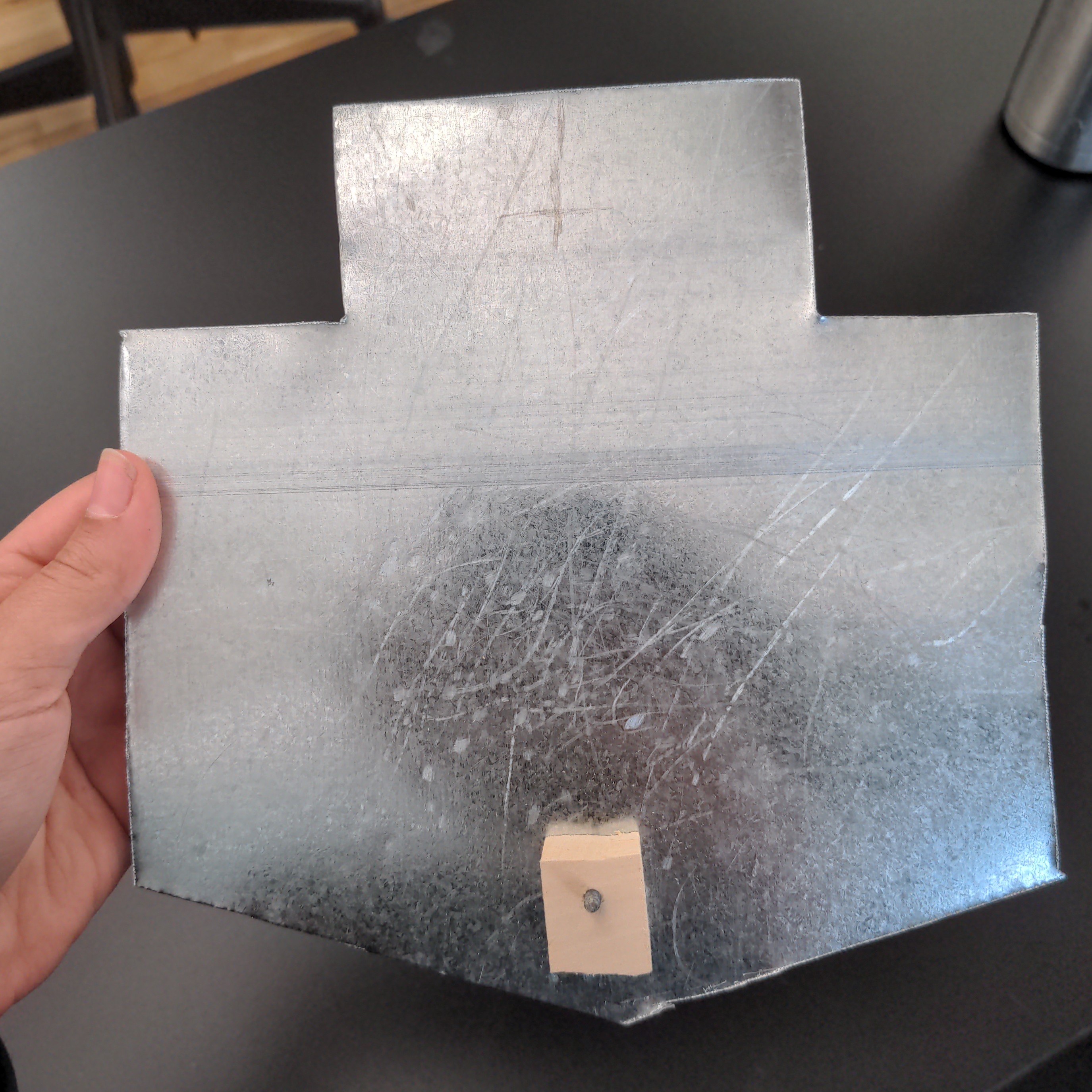

At this point it was tired and late so I just cut another $8 sheet of steel quickly, clamed the handle pieces down together and to the sheet metal and screwed in two screws. I do not like how it looks and the edges are too sharp.

Weird Shield Side View | Weird Shield Back :————————-:|:————————-:  |

|

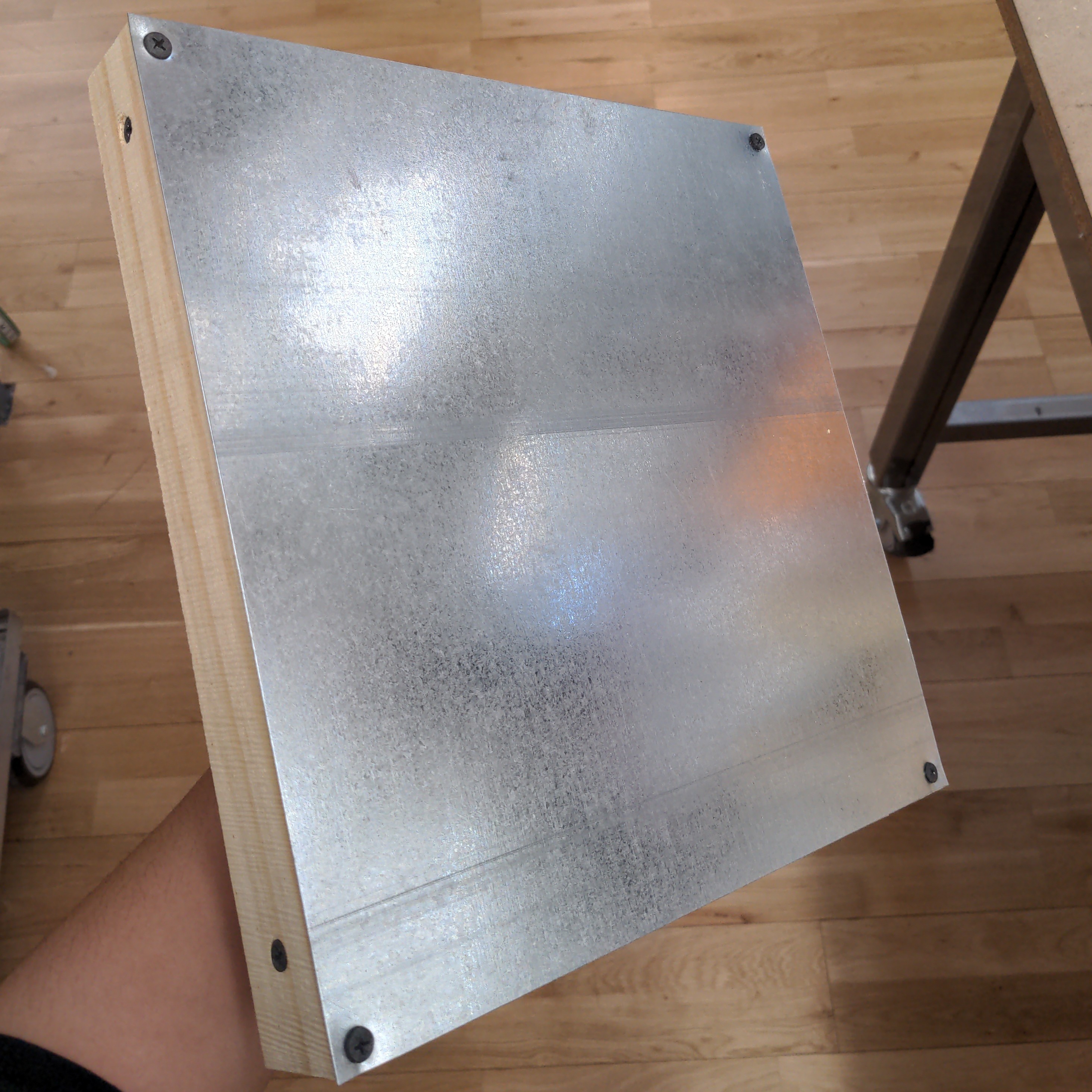

Finally in a fraction of the time spent in earlier mentioned efforts, I returned to the shot and recreated a more minimalist design of the shield which is quite similar to what one side of the display box I was originally planning would look like.

Front of Shield | Back of Shield :————————-:|:————————-:  |

|